Services

Whether you're a CEO, small business owner, or freelancer, you'll encounter tasks outside your expertise, such as payroll, bookkeeping, PR, web design, or tax help. Specialized companies can handle these tasks.

In personal life, outsourcing chores like cleaning, house help, finding housing, or job placement is common. Many companies offer services to meet these needs.

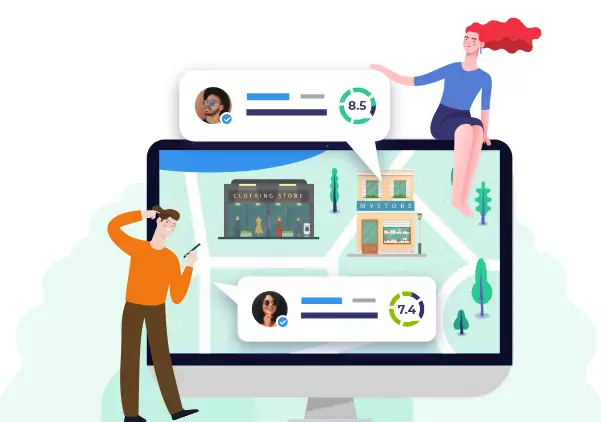

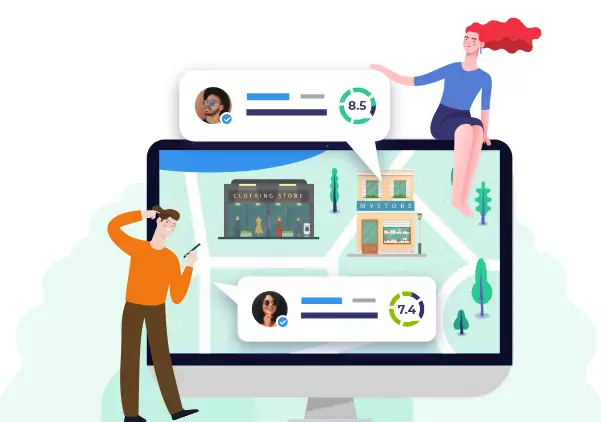

But how do you ensure you’re dealing with a trustworthy company? For sensitive services involving personal and business details, it's crucial to verify credibility.

Always read reviews and customer feedback to gauge a company's reliability. Share your own experiences, positive or negative, to assist others in making informed decisions.