788 companies

Services

...

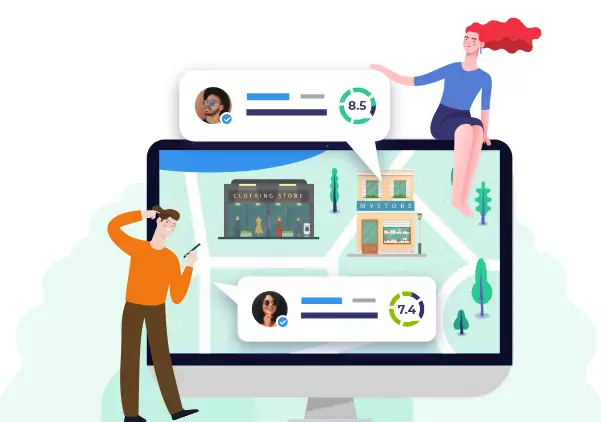

Experiences with Services

Consumers looking to compare service providers often seek reliable options for cleaning, landscaping, or personal training. Common pitfalls include hidden fees, inconsistent service quality, and lack of communication—imagine hiring a cleaner who misses spots or charges unexpectedly. Avoid surprises by exploring our company listings and reading reviews. Feel free to share your own experience to assist others in making informed decisions.

Companies

7 reviews

24 reviews

27 reviews

23 reviews

20 reviews

83 reviews

10 reviews

1 reviews

4 reviews

1 reviews

1 reviews

26 reviews

20 reviews

10 reviews

26 reviews

2 reviews

19 reviews

28 reviews

8 reviews

33 reviews

24 reviews

21 reviews

21 reviews

22 reviews

28 reviews

8 reviews

1 reviews

2 reviews

20 reviews

1 reviews

28 reviews

4 reviews

25 reviews

19 reviews

8 reviews

17 reviews

8 reviews

16 reviews

25 reviews

25 reviews

3 reviews

25 reviews

8 reviews

8 reviews

25 reviews

25 reviews

8 reviews

8 reviews

30 reviews

23 reviews

7 reviews

6 reviews

22 reviews

17 reviews

23 reviews

17 reviews

23 reviews

27 reviews

9 reviews

17 reviews

8 reviews

18 reviews

21 reviews

28 reviews

16 reviews

18 reviews

7 reviews

26 reviews

8 reviews

8 reviews

17 reviews

20 reviews

20 reviews

20 reviews

23 reviews

24 reviews

21 reviews

18 reviews

21 reviews

9 reviews